4.02.2014

4.02.2014

Algol Group celebrates 120 years

This year marks the 120th anniversary of Algol, a family-owned multi-branch company with an international reach, and one of only a few dozen family businesses in Finland with such a long history under its belt. The Group is made up of five subsidiaries that import and manufacture a wide range of products for industry and the health care sector.

Algol Technics imports Demag components, which are widely known in the technology sector for their use in crane installations in industrial halls and warehouses. Demags are standard issue in Algol Technics’ range of products – complete kits ready to install almost as is. The “darlings” and the apples of the company’s eyes are the large process cranes, manufactured at a production site in Herttoniemi. With annual production measured in tens, each of these cranes has their own nickname, and they’re watched with keen interest through every step of their life cycle.

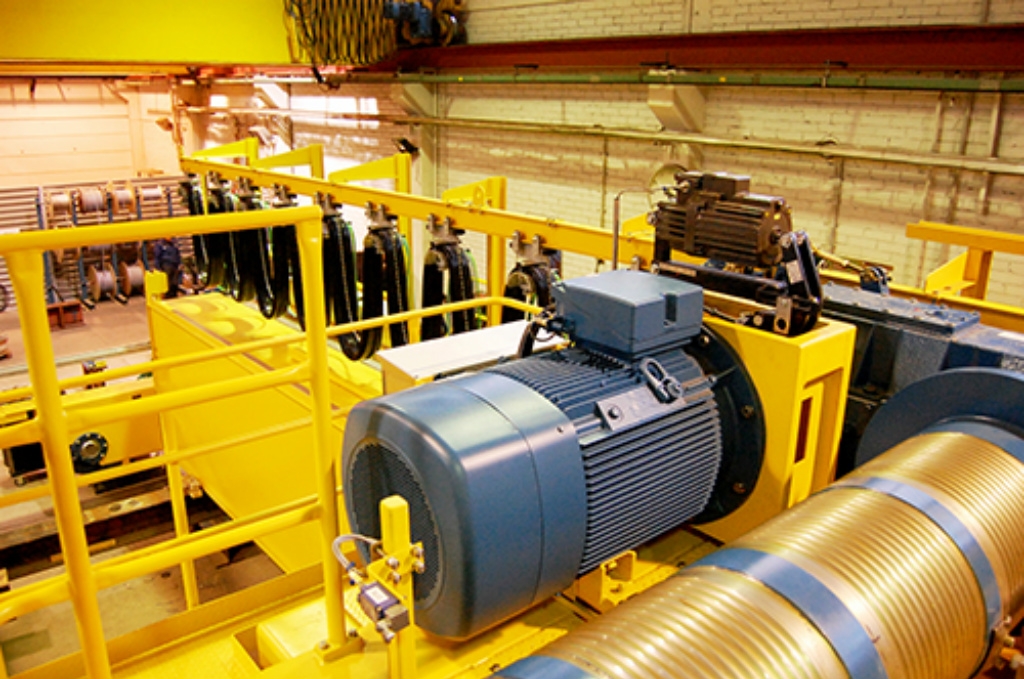

A 31.5-metre crane – the third in a series of five cranes – being tested prior to delivery at Algol Technics’ production site in Herttoniemi.

Many process cranes are powered by heavy-duty VEM motors, known for their longevity and durability.

“For many years now, Demag’s choice for its large hoisting machinery has been VEM, with motors specifically designed for service on cranes. This is what led us to extend our partnership with VEM motors Finland to include our own larger-size process cranes. VEM has provided expert service,” says Harri Laurén, Purchasing Manager at Algol Technics. The two companies serve largely the same customer base, so both brands had already found favour with the customers before going into the partnership.

“Cast iron motors are durable and ensure a high level of reliability for crane applications,” explains Engineering Manager at Algol Technics, Harri Sölli. For crane duty, the motor rating must be selected on the basis of continuous duty operation to guarantee successful load handling under all circumstances. In most cases, motors are ordered fully assembled, with the pulse sensor, heating elements or thermistors already fitted in place during the manufacturing process.

Engineering Manager Harri Sölli (left) and Purchasing Manager Harri Laurén, pictured in a crane trolley during a test run, seem a bit sad at the idea of having to part with the lovingly built crane now awaiting delivery.

A VEM motor in action.