19.02.2014

19.02.2014

Metso receives two repeat orders for Altay Polimetally’s mine in Kazakhstan

With Metso, the whole copper ore process of the mine will be handled with one solutions provider

Metso has signed two repeat orders with Altay Polimetally LLP for their open pit copper mine in Almaty, Kazakhstan. The orders include the design, supply, installation and commissioning of complete secondary, tertiary and quaternary crushing and screening plants as well as an automation system. The combined value of the orders is EUR 25 million. The two new contracts follow the delivery of the world’s biggest fully mobile crushing and conveying system, signed in June 2012 for a value of EUR 11 million.

“For our new copper ore deposit, we need cost efficient processes and reliability based on a seamlessly working partnership. We do not need multiple intermediaries, and by choosing Metso, we are working with a market leader who has a long experience in mining and construction operations,” says Mr. Yun, Dr. of Technical Sciences, CEO and Chairman of the Board, Altay Polimetally LLP.

“These major orders demonstrate Metso’s strength in offering equipment and process know-how to meet the customer’s operational requirements. Our close collaboration with Altay Polimetally during the design of the project certainly contributed to choosing Metso as the sole solutions provider,” comments Serge de Backer, Business Manager, Crusher Systems, Mining and Construction, Metso.

To achieve the customer’s objective for a minimum number of operators, Metso also supplies Altay a complete automation system to run the whole process. The electrical systems can withstand the harsh climatic conditions (from +30°C to -30°C) and provide efficient plant control.

The secondary and tertiary crushing plant order was included in Metso Mining and Construction’s fourth quarter 2012 orders received, and the quaternary crushing plant in the first quarter 2013 orders received. The installations will be delivered by July 2014.

Crushers to allow high output

The secondary and tertiary plants include one GP500S cone crusher with large feed opening, and two HP5 cone crushers with high reduction ratio. Two high-efficiency MF 3085-2 screens will be used for screening. The planned output of the copper ore processing plant is 550 metric tons per hour, resulting in 3 million tons per year of 0/10 mm sized end products. The quaternary crushing plant will produce 0/3 mm sized ore with a capacity of 450 metric tons per hour. Two Barmac 9100 vertical shaft impactors are used, one of them in operation and one stand-by. Here, another two MF 3085-2 screens are used.

Altay Polimetally LLP, based in Almaty, Kazakhstan, will extract at the new mine copper ore including gold. The planned ore extraction will be 3 million tons per year, and including host rock 10 million tons. The CEO and Chairman of the Board of Altay Polimetally LLP Mr Yun previously held the position of CEO of Kazakhmys Corporation between 1995 and 2006. He was instrumental in increasing the production of copper cathodes from 90,000 to 420,000 tons per year.

Locotrack L200 to Kazakstan

Update December, 2014 (Metso’s customer magazine, text Eero Hämäläinen)

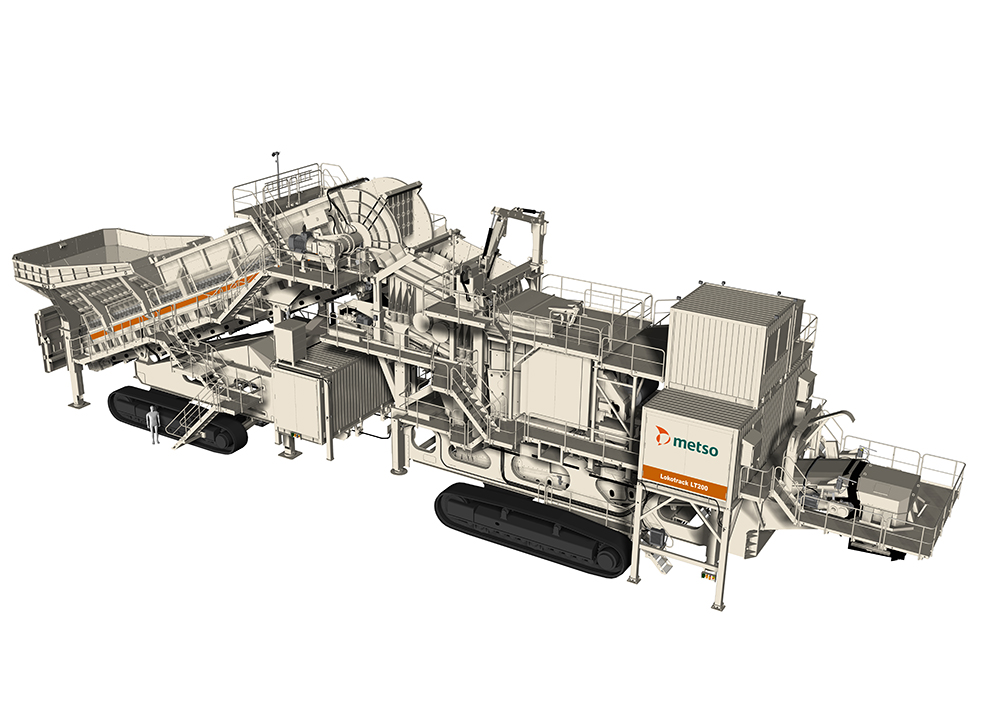

The tracked giant ready for Kazakhstan

The assembly of a recordbreaking, mobile trackmounted jaw crushing plant has been completed at Metso’s production facility in Finland. The monster plant is now ready to be dismantled and shipped to Kazakhstan for on-site assembly.

The world’s largest fully mobile trackmounted jaw crushing plant is truly a machine of superlatives:

- total weight more than 800 tons

- height almost 11 meters

- capacity up to 2500 tons per hour

- fully electric-driven with an incoming

- power range of 6000 volts

AMAZING JOURNEY

More than 65 truck and train wagon loads are needed to transport all the pieces the 3,000+ kilometer distance from Finland to Kazakhstan. The heaviest single item to be transported is the 90-ton apron feeder, a part of the mobile apron feeder.

JAWS UP FOR HUGE ORE LUMPS

The giant C200 jaw crusher inside the LT200 can process a copper ore lump of up to 1.2 meters in size.

During one year, 13 million tons of material will pass through the crusher.

Read the whole article from Metso’s customer magazine, page 44 >>

|

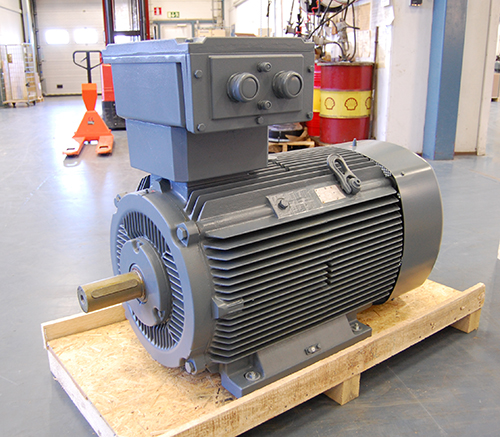

VEM MOTORS FINLAND has delivered the motors for the crushing and conveyor system. The delivery includes 24 pieces VEM IE2 motors with IEC sizes 160-315 and one IEC400 slipring motor manufactured by AEM. The motors give the giant a total power of 1,9 MW. VEM IE2 squirrel-cage motor K21R 315 MX6 NS LL TPM HB IL KV HW, 1210 kg, IP 55 waiting for delivery in VEM MOTORS FINLAND’S stock |

|