20.12.2022

20.12.2022

VEM contributes to environmentally friendly ferries

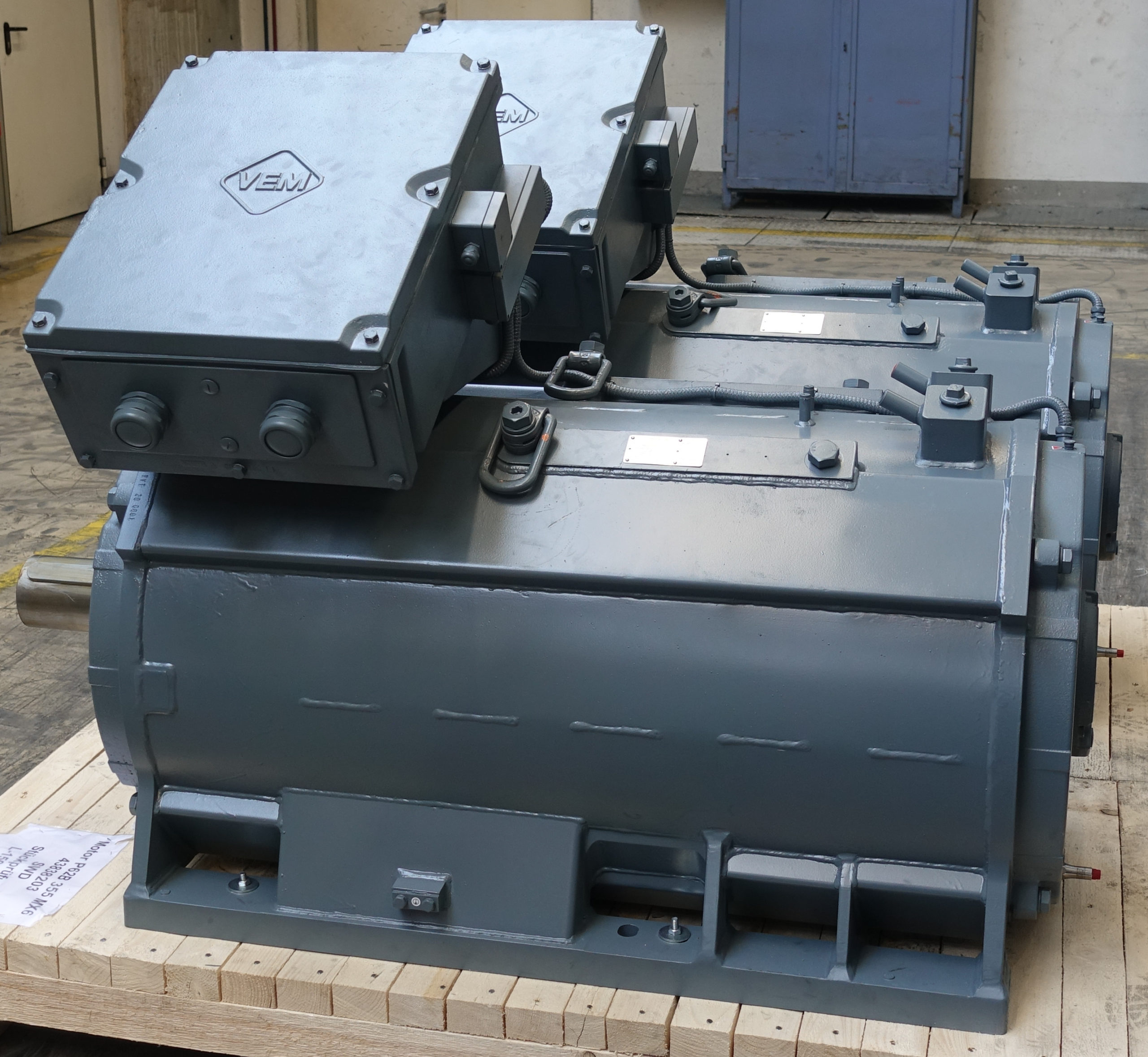

Water-cooled permanent magnet motors of VEM

Making ships more environmentally friendly is not easy, especially when converting a ferry built in 1965. This was the challenge faced by a long-standing partner of VEM when asked to equip a ferry with electric drive systems.

Combining tradition and modernity – emission-free retrofit projects in marine transport

The passenger and car ferry, which weighs almost 400 tons, can carry up to 450 passengers and 27 cars on one trip across Lake Maggiore. Previously, two diesel engines with an output of 310 kW each powered it. First step was to replace the old and less environmentally friendly drive system. Second step was to redesign the entire propeller system. Highly efficient fixed-pitch propellers replaced the high-maintenance variable-pitch propellers. Variable-speed drives determine the drive characteristics now. Moreover, all this with significantly increased efficiency, especially in the partial-load range. This also reduced the complexity of the entire system. A decisive advantage for the operator of the fleet. Battery and hybrid technology significantly reduced fuel consumption.

The batteries are charged via an on-shore connection. This meant a complete retrofit of the ferry’s connections and interfaces.

VEM cooperates successfully in shipbuilding

To equip an over 50 year’s old ferry with an electric drive was clearly a challenge. As a result, a completely new integrated DC system regulates the power flow on board between the battery, the navigation system and other consumption.

The VEM plant in Wernigerode took over the production of two identical water-jacket-cooled permanent magnet motors for the ferry. The motors drive directly the propeller shaft. This meant that the gearboxes could be dispensed with – an important step in terms of optimizing efficiency. The super compact design of the new drives is ideally suited to retrofit applications, as deck heights and installation spaces are often limited.

VEM – a German brand at the highest level

The VEM group develops and manufactures generators and motors for small and large ships worldwide. Its factories produce propeller motors with an output of up to 40 megawatts.

VEM revised the water-cooled permanent magnet motor series just recently. Standardization and suitability for a wide range of marine applications were the development goals. Thanks to the permanent magnet technology and the necessary converters, a broad speed-adjustment range is possible. This is where the full benefits of permanent magnet technology come into play – exceptionally high efficiency in the partial-load range with minimal installation space. Thus, VEM was able to provide an optimal solution for the project. In addition, the water-jacket-cooled design helped to reduce noise emissions. This was another of the client’s goals. VEM PM motors are available in both horizontal and vertical orientation across a broad power range.

The VEM Group’s decades of experience in the development of customized drives guaranteed the success of this retrofit project. The rotor geometries were completely redeveloped and their installation optimized. The use of embedded magnets ensures an extremely long service life for the components and once again demonstrates the high quality standards of VEM motors.

A strong partner at your side: punctual, reliable, innovative

Following this success, other ferry operators have already shown interest in this kind of retrofitting. VEM will be happy to help them make their ships safer, quieter, more energy-efficient and emission-free.

VEM news 19.12.2022